An Unusual Enginectomy

Part I:

This is the story of my performing an enginectomy on my Jeep Scrambler.

The Motor Choice

My desire was to swap the gas motor for a diesel motor. After a fair bit of research, I came to the disappointing conclusion that there isn't an American diesel motor that would fit the jeep very well. The old ford and Chevy diesel motors were not that great of motor and really heavy, thus causing issues with the suspension. The new Powerstroke (in Fords) and Cummins (Dodge) were huge and heavy. To fit one of these motors would take suspension AND body modifications. My Scrambler is far to cool to turn into Frankenstein's bride.

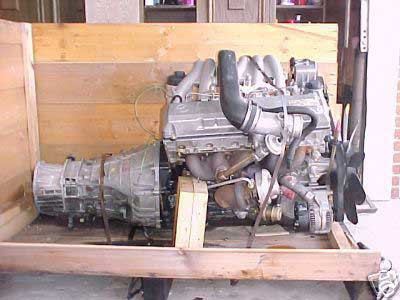

Just as I was about to give up hope on finding a diesel motor, when a buddy sent me a URL from an E-bay auction and told me I had to check it out immediately. Well I did and this is what I found.

The motor is a Mercedes Benz 2.9 Liter inner-cooled turbo-diesel with a 5-speed gearbox!

To make a long story short, The fellow selling the motor had some kind of relationship with a Dyno testing lab in Detroit. I was told the motor was sent from Germany in the pictured crate to the testing lab, tested for approximately 100 hours, and promptly forgotten about until the labs management said "get this thing out of here."! I won the auction but was under the reserve (no suprise). The fellow and I went back and forth on the motors value until a deal was struck for. $1900.00!

Research

Testing

After he got my money he explained to me that he had NO mechanical skills and that he wasn't sure if he could even get it on a truck! Needless to say, I got a little nervous at that point. I suggested that he hunt around the testing lab and see if the rest of the box was still around. A few days later he called me and said that he found the remainder of the crate and a neighbor that knew how to use a hammer.

A week later I took delivery of my new Mercedes turbo-diesel motor in its original crate!

Now that I had the totally trick motor, I had to find out information about it. Unlike American motors where one can find out just about everything, The MBZ 602 DE2.9LA motor I had was an enigma. It seems that our brothers on the other side of the pond are restricted from freely performing enginectomys at their pleasure, thus detailed information about vacuum circuits and the wiring harness is near impossible to obtain.

I sent out a call for help on MBZ G-wagon chat groups and got an immediate reply from a guy in New Zealand that was putting the same motor in his G-wagon. Man, talking about a small world. He and I then collaborated on getting our information. We found out that the DE2.9LA MBZ motors are the same motors that MBZ uses in the US Marine Corps "fast attack" G-wagons and a tuned down version in being put in the new Dodge Sprinter vans. This came as a huge relief, now I knew that I could get parts.

The first action after uncrating the motor was to see if she ran. I took a steel utility cart and welded some raisers onto it then welded plates onto the raisers that I could mount the motor to. I then mounted a plywood plate to the cart then mounted the Bosch computer and wiring components to it. I then added a battery, ignition switch, and fuel tank to the cart. It then took some hose fittings, a radiator hose and a hose clamp to hook up a garden hose to supply the coolant circuit. After consulting my German / English dictionary, I got all the wires plugged in correctly and BINGO! She fired right up!

Running on the test bed, the motor was suprisingly quiet and calm...I on the other hand was bouncing around and making all kinds of klatter...In glee!

| An Unusual Enginectomy Part II |